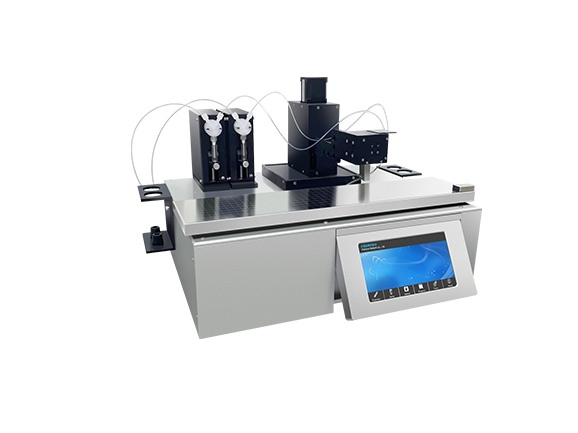

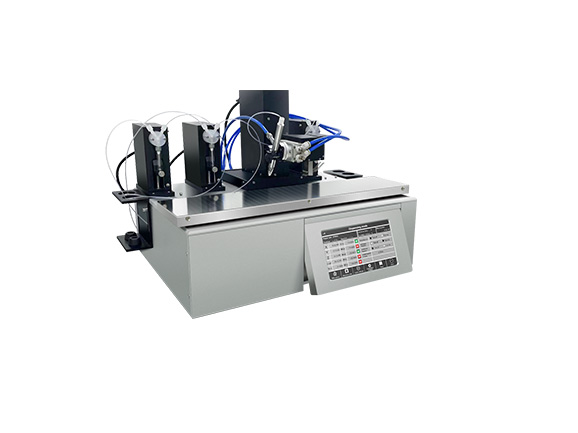

With experience in customized automation, our IVD equipment is designed to cover needs from small to super large-scale production. Featured products are Table Top Dispenser, Continuous Dispenser, NC membrane Lamination Machine, Multiple components Automatic Lamination Machine, Sample pad treatment and Drying Machine, DOA panel Labeling Machine, etc. All the equipment can be customed to meet your specific requirement.

IVD device manufacturing is a critical process that requires precision and accuracy. IVD machines play a crucial role in the IVD manufacturing processes, and therefore, it is essential to maintain their quality and performance to ensure consistent and reliable results One way to ensure quality control in IVD manufacturing is by implementing routine maintenance checks on IVD machines. This includes regular inspections, cleaning, and calibration of the machines to ensure they are functioning optimally. This will help detect any issues early on, allowing for timely repairs and replacements if necessary. It is also important to ensure that operators are adequately trained to use the IVD machines. This will prevent mistakes that could affect the quality of the end product.

Furthermore, IVD manufacturers should adhere to strict standards and regulations set by organizations such as the FDA and ISO to ensure that their products are safe and of high quality. This includes implementing quality management systems that cover all aspects of the manufacturing process, including IVD machines.

In summary, quality control plays a crucial role in ensuring that IVD manufacturing equipment such as IVD machines perform optimally, thus producing consistent and reliable results. By implementing routine maintenance checks, ensuring operator training, and adhering to quality standards and regulations, IVD manufacturers can produce high-quality products that meet the needs of healthcare professionals and patients.

The quality of the materials used in IVD manufacturing equipment directly affects the performance of the final product. As such, IVD manufacturers need to use high-quality materials in their equipment. For instance, some lateral flow dispensers use precision-engineered stainless-steel plates that ensure accurate dispensing of reagents. Other advanced IVD materials used include ceramic components that offer better durability and corrosion resistance than traditional materials.

Using advanced materials in IVD equipment not only improves their accuracy but also extends their lifespan. It enhances the quality of the final product and reduces the frequency of maintenance and replacement.

Maintenance is crucial in ensuring that IVD manufacturing equipment performs optimally and remains reliable. Manufacturers need to conduct regular maintenance and calibration to detect malfunctions early and prevent unexpected downtimes. Such maintenance schedules should include the calibration of IVD machines and the cleaning and sanitization of IVD test strips.

Yet, despite regular maintenance, some malfunctions or technical issues may still emerge in IVD manufacturing equipment. In such instances, troubleshooting guides or manuals should be available to help operators identify and fix any issues. Manufacturers should provide detailed installation and troubleshooting guides to users to help them become more familiar with the equipment and prevent issues from arising in the future.

Lean Manufacturing has become a popular approach to streamlining the production of IVD (In-Vitro Diagnostics) Manufacturing Equipment. By implementing Lean Manufacturing principles, IVD Manufacturing Equipment manufacturers can greatly reduce costs and increase efficiency. This can lead to a better return on investment, as well as improved customer service and satisfaction.

One of the key benefits of Lean Manufacturing is the elimination of waste within the manufacturing process. By streamlining processes, manufacturers can reduce the amount of time and resources required to produce IVD Manufacturing Equipment. This can result in shorter lead times, lower production costs, and a greater focus on quality.

Lean Manufacturing also helps to reduce manufacturing defects. By eliminating rework and scrap, manufacturers can reduce the amount of time and resources needed to produce IVD Manufacturing Equipment. This can lead to improved product performance and quality.

Lean Manufacturing can also reduce the amount of inventory required for production. By tracking inventory levels and optimizing production, manufacturers can reduce the number of resources needed to produce IVD Manufacturing Equipment. This can help to reduce overhead costs.

Finally, Lean Manufacturing helps to improve the overall communication within the organization. By using continuous improvement techniques, manufacturers can identify and resolve any issues in the production process. This can lead to improved customer service and satisfaction.

Overall, Lean Manufacturing is an important tool for IVD Manufacturing Equipment manufacturers. By reducing waste, improving quality, and reducing overhead costs, manufacturers can increase efficiency, reduce costs, and improve customer satisfaction.